Sectors

CEVILOG has customers across a broad range of sectors of industry, bringing them solutions that meet their constant concern to improve the quality of their product as well as to make economic savings.

See our applications in different sectors of industry.

Pharmaceuticals

100% inspection of production for greater health safety and traceability.

Inspection of capsules

- Checking the integrity of the capsule.

- Checking the product’s appearance and for cosmetic defects.

- Counting items in blister packs.

Code reading

-

Reading of codes on packets (bar codes, Datamatrix, etc.).

-

Reading to double-check batch numbers and use-by dates.

-

Implementation of serial numbering solutions.

Cosmetics

Inspection of every product to guarantee quality and aesthetics.

Inspection of packaging

- Presence of different components (bottles, tops, leaflets).

- Checking the appearance and aesthetics of the box.

- Foolproof systems to distinguish different batches and similar products.

Assembly of mascara tubes

-

Positioning and orientation of the tubes.

-

Checking the integrity of the mascara brush.

-

Inspection after assembly and boxing.

Agri-food

Reliable controls to guarantee food safety.

Bottle inspection

-

Checking fill levels.

-

Checking the presence of bottle tops, that they are screwed up and the tamper-evident ring is present and intact.

-

Presence and positioning of labels on bottles.

Inspection of pizzas

-

Checking the geometric shape of pizzas.

-

Checking the presence and even distribution of all the ingredients on the surface.

Automotive

Automating processes while guaranteeing optimum quality.

Checking car rear windows with an infrared camera

-

Checking rear window defrosters are working properly.

-

Checking that primer is correctly applied before depositing the adhesive.

Inspecting tyres

-

Reading the codes on tyre sidewalls.

-

Locating and picking up tyres from racks.

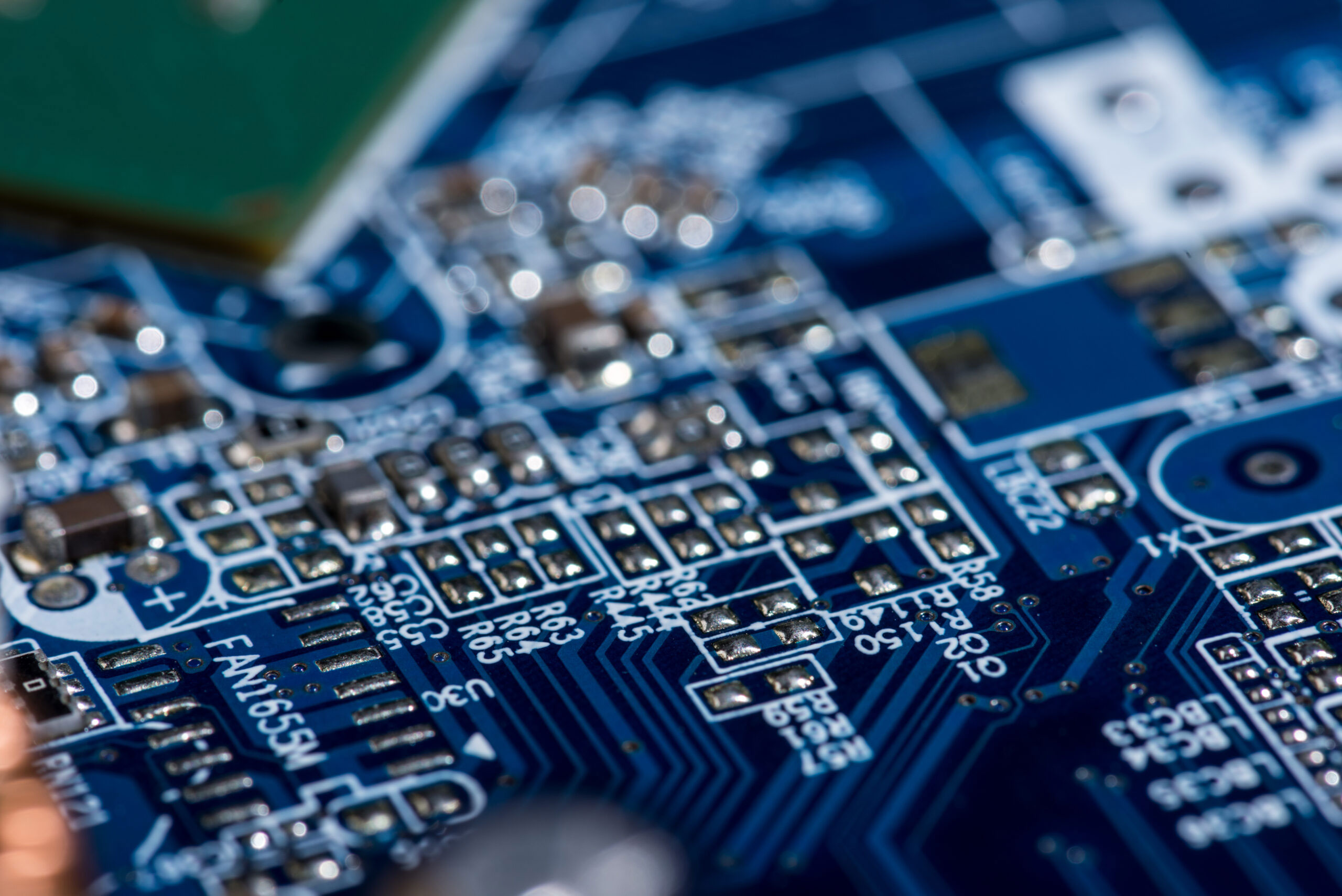

Electronics

Total inspection to ensure optimum product functioning.

Checking weld seams

-

Detection of welding and soldering defects in components (gaps, wires too near the surface, weld appearance).

Checking of pad printing quality

-

Checking print quality against an image using artificial intelligence.

Logistics

Automated scanning to guarantee traceability.

Code reading

-

Reading of codes on boxes and pallets (bar codes, Datamatrix, etc.).

Automatic batch checking using cobots

-

Automatic reading of codes on products in boxes by cobots.

-

Checking the integrity of incoming batches.